Asia

COATED AND BUILDING PRODUCTS

Our Coated and Building Products Asia group comprises metal coating and painting operations in Indonesia, Thailand, Malaysia, Vietnam and China; BlueScope Lysaght businesses across Asia; BlueScope Butler pre-engineered building operations in China; and an Indian joint venture with Tata Steel that includes mid and downstream operations.

Asia regional summary

The 2007/08 financial year was one of improved performance across our Asia business. Revenue for the year increased by 14 per cent to $1.570 billion, largely due to increased sales volumes and prices across the region. During the year, we undertook a $225 million impairment of our China and Vietnam coating facilities that affected profitability, resulting in a reported EBIT loss of $148 million. Without the impairment, underlying EBIT was $76 million, an increase of 73 per cent, reflecting higher sales, improved margins and lower unit costs.

Stronger sales pricing and lower coating metal costs helped offset higher steel feedstock prices, while reduced business development costs in China and India also had a positive effect on earnings. Our Asia businesses operate in highly diverse economic and political environments. While some factors influence business at a regional level, there is significant variation in their respective domestic situations.

China

The highlights for our China businesses in 2007/08 were improved financial performance from BlueScope Butler, strong operational performance from our Suzhou metal coating facility and an improved second half from Lysaght. These improvements were the result of a thorough strategic management plan that enabled our China businesses to finish the financial year in a cash-positive position. BlueScope Butler is now well positioned to grow, while we continue to fine tune costs.

Our new Suzhou metal coating and painting operation performed very well in its first full year. It is continuing to ramp up towards capacity and has proved itself comparable to any facility in the BlueScope Steel portfolio. In July 2007, our Lysaght business in China was demerged from BlueScope Buildings, becoming more regionalised and closer to customers, resulting in steady month-on-month performance improvements. In safety, our China businesses remained strong. Additional training of supervisors is ensuring that safety fundamentals are understood and acted upon by all our people.

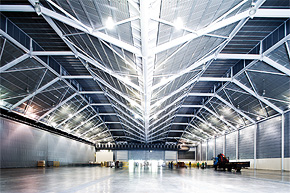

The advantages of high quality, lightweight steel-framed buildings are becoming more widely appreciated in China and demand is growing for better quality steel structures. During the year, we were involved in the supply of products and expertise to some prestigious Olympic sites, which will further consolidate our reputation in the premium end of the market. Looking ahead, we are aiming to be involved in the Shanghai World Expo in 2010 to further raise our profile.

Aris Widodo, Production Supervisor, at our Lysaght facility in Citibung, Indonesia. Our downstream businesses in this country had a very strong year with despatches up 35 per cent and a solid improvement in safety performance.

The 2007/08 financial year was one of improved performance across our Asia business.

Thailand

The safety performance of our Thailand businesses was a standout achievement for 2007/08, with a Lost Time Injury Frequency Rate of zero. This excellent result was achieved over 21 million working hours. This is an extraordinary effort, even by the very high standards of BlueScope Steel.

Thailand was more politically stable over the last financial year, as the new Thai government brought improved business confidence to domestic markets. A number of projects that were on hold under the previous government became active. In financial terms, our Thailand operations had a strong year, with record earnings representing a significant increase on the previous year.

Our new PEB facility in Thailand performed well during its first full year of operations and the business has started to build a strong customer base for its market offer.

Unfortunately the improvement in the political situation has been questioned, and during mid 2008 the country has experienced another deterioration in economic sentiment.

In the coming year, we will be concentrating on downstream growth in Thailand, in our PEB and residential markets, as well as growing our midstream sales domestically to capitalise on the expansion of the second metal coating line completed during 2005. In addition, we are progressing with an expanded sales strategy into Laos to capitalise on the boom in tourism, mining and transport that is occurring in that country.

Vietnam

In Vietnam, no Lost Time Injuries were sustained during the construction of our new metal coating and painting facility near Ho Chi Minh City. This facility is now in production and operating close to capacity, with further progress being made in growing domestic markets as well as exports to selected target markets including Indonesia, Cambodia and the Philippines.

The financial impairment undertaken during the year was related to an unstable regulatory environment, with earnings affected by frequent changes to government tariffs on our steel raw materials and on the coated flat products range. Inflation of above 20 per cent in the Vietnamese economy has led to government tightening of liquidity, thereby decreasing investment in many sectors, including building and construction. During the year, our new PEB plant near Ho Chi Minh City commenced operations. We continue to focus on growing both the domestic and foreign direct investment sectors for steel solutions, in particular PEB and SMARTRUSS® framing.

We have two key priorities in Vietnam in the coming year. The first is to increase sales into the premium end of the domestic market.

We aim to achieve this by broadening our channels to market, actively engaging specifiers and winning a higher share of customers’ business. Our second priority is supply of product to support market seeding for our new Indonesia facility. We will continue to use product from our Vietnam operation to generate demand in Indonesia.

Revenue for the year increased by 14 per cent to $1.570 billion, largely due to increased sales volumes and prices across the region.

Indonesia

Our Indonesia businesses performed well in 2007/08. Our metal coating and painting facility at Cilegon exceeded its designed capacity, setting production records despite down time for a major equipment replacement. Sales volumes rose 40 per cent on the previous year.

Construction of project Badak, our second metal coating line at Cilegon, is progressing well. The facility is on-time, on-budget and due for commissioning at the end of the 2009 calendar year. It will bring an additional 170,000 tonnes of metal coating and in line painting capacity to our Indonesia operations. Our markets are undergoing robust growth, with additional demand being met by our metal coating plants in Malaysia and Vietnam.

Our downstream Lysaght and PEB businesses had a very strong year. Despatches were up 35 per cent year-on-year, and approval was gained for a wide coil roll-forming process, which will provide for an improved value proposition through greater coverage as well as efficiency and speed of installation.

All our sites in Indonesia retained the Environment Management Systems Standards ISO 14001 certification and we are among the few companies to have been awarded 'Green Company' status by the Indonesian Government. We also showed a solid improvement in safety, maintaining zero LTIFR and reducing MTIFR by 13 per cent, while having additional contractors working on the construction of our second metal coating and painting line. We are emphasising our safety values through a local community campaign aimed at improving road safety, a major problem in this country. Next year, our main challenges are to complete the project Badak on time, grow domestic sales, increase our steel buildings penetration, and involve all employees in value improvement and cost reduction initiatives.

Malaysia and Singapore

Our Malaysia businesses consolidated their turnaround phase by delivering record results in 2007/08. Manufacturing performance improved to record levels in areas including prime first time, plant up-time and overall efficiency. BlueScope Steel Malaysia made a significant improvement in safety, maintaining a zero LTIFR while reducing MTIFR by 35 per cent. Our Singapore businesses also performed very well with a year on year sales growth of 23 per cent.

Approval was granted for a wide coil forming process in our Lysaght Malaysia and Singapore businesses. This will deliver an improved value proposition through advantages in coverage as well as efficiency and speed of installation. In the year ahead, we will continue to grow domestic sales, focusing on sales of premium products, and ensure reliable supply to our core markets. We expect healthy sales from our PEB business and will seek the involvement of all employees in value creation and cost reduction initiatives.

India

Opportunities for our businesses increased during the year, as India became the world’s second largest destination for foreign direct investment capital. Demand for steel buildings is growing due to shorter construction times and competitive pricing of steel compared to other building materials. In 2007/08, our PEB facilities operated at full capacity, largely due to strong domestic demand and improved marketing strategy. The India PEB industry continues to expand, having increased by a factor of 40 in the last eight years.

Work is progressing well on our new $270 million joint venture metal coating and paint line project at Jamshedpur. The project is on schedule for completion in the 2010 calendar year. Our safety performance in India has also been very good. The Jamshedpur coated steel project has passed one million hours without LTI or MTI, while our plant at Pune has worked one million hours LTI free.